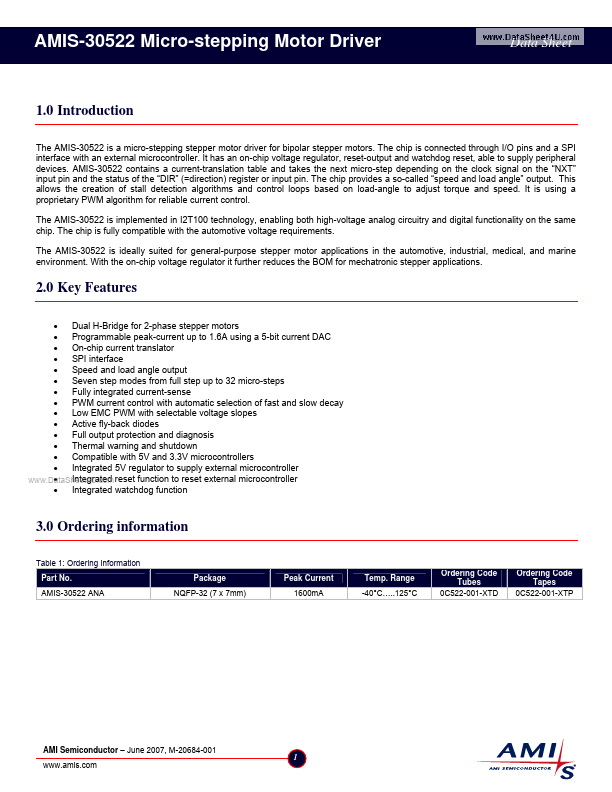

AMIS-30522 Description

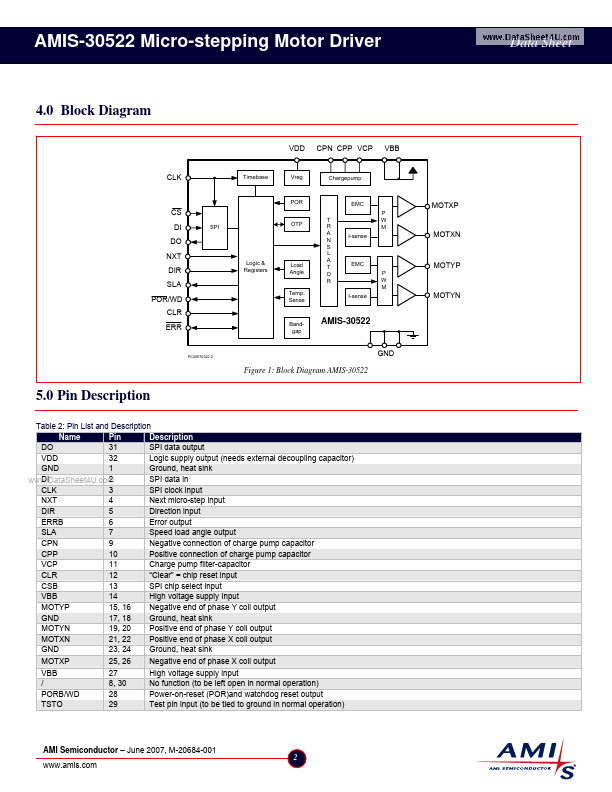

Pin List and Description Name Pin Description DO 31 SPI data output VDD 32 Logic supply output (needs external decoupling capacitor) GND 1 Ground, heat sink DI 2 SPI data in .. CLK 3 SPI clock input NXT 4 Next micro-step input DIR 5 Direction input ERRB 6 Error output SLA 7 Speed load angle output CPN 9 Negative connection.

AMIS-30522 Key Features

- Dual H-Bridge for 2-phase stepper motors

- Programmable peak-current up to 1.6A using a 5-bit current DAC

- On-chip current translator

- SPI interface

- Speed and load angle output

- Seven step modes from full step up to 32 micro-steps

- Fully integrated current-sense

- PWM current control with automatic selection of fast and slow decay

- Low EMC PWM with selectable voltage slopes

- Active fly-back diodes

AMIS-30522 Applications

- Dual H-Bridge for 2-phase stepper motors

- Programmable peak-current up to 1.6A using a 5-bit current DAC