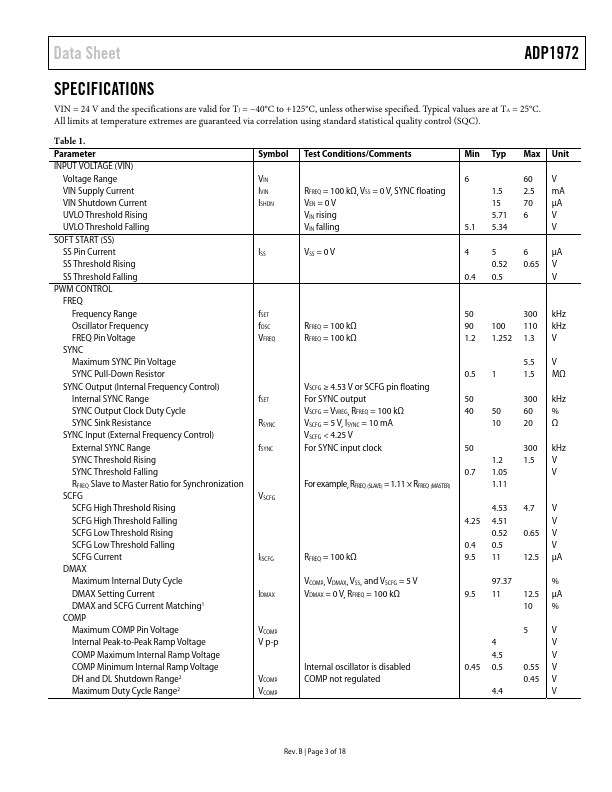

ADP1972 Overview

The ADP1972 is a constant frequency, voltage mode, pulse-width modulation (PWM) controller for buck or boost, dc-to-dc, asynchronous applications. The ADP1972 is designed for use in asynchronous battery testing applications with an external, high voltage field effect transistor (FET), half bridge driver, and an external control device, such as the AD8450. The asynchronous device operates as a buck converter in...