KDV08 Overview

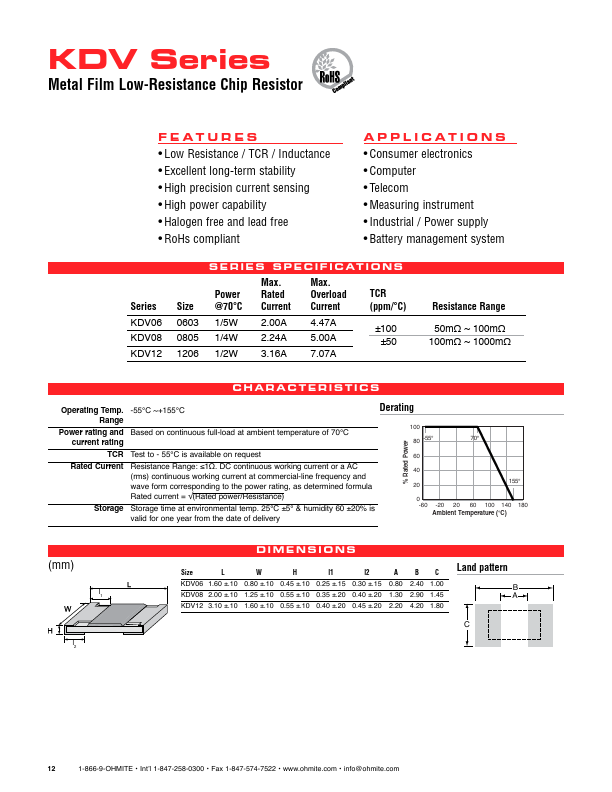

KDV Series Metal Film Low-Resistance Chip Resistor F e at u r e s Low Resistance / TCR / Inductance Excellent long-term stability High precision current sensing High power capability Halogen free and lead free RoHs pliant A p p l i c at i o n s Consumer electronics puter Tele Measuring instrument Industrial / Power supply Battery management system Series KDV06 KDV08 KDV12 Series Specifications Max. Range Power...

KDV08 Key Features

- i c at i o n s • Consumer electronics • puter • Tele • Measuring instrument • Industrial / Power supply • Batt