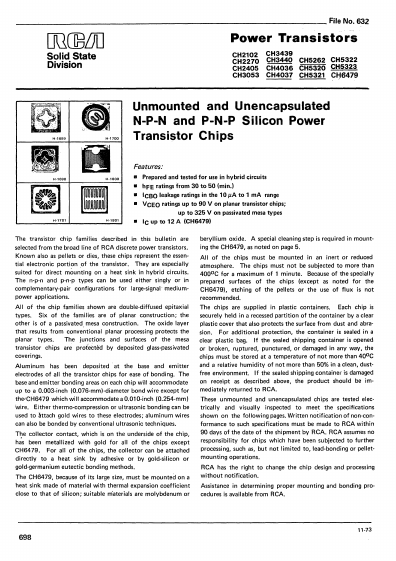

CH5321 Overview

_ _~_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ FileNo.

CH5321 Key Features

- Prepared and tested for use in hybrid qircuits

- hFE ratings from 30 to 50 (min.)

- ICBO leakage ratings in the 10 IlA to 1 mA range

- VCEO ratings up to 90 V on planar transistor chips

- IC up to 12 A (CH6479)