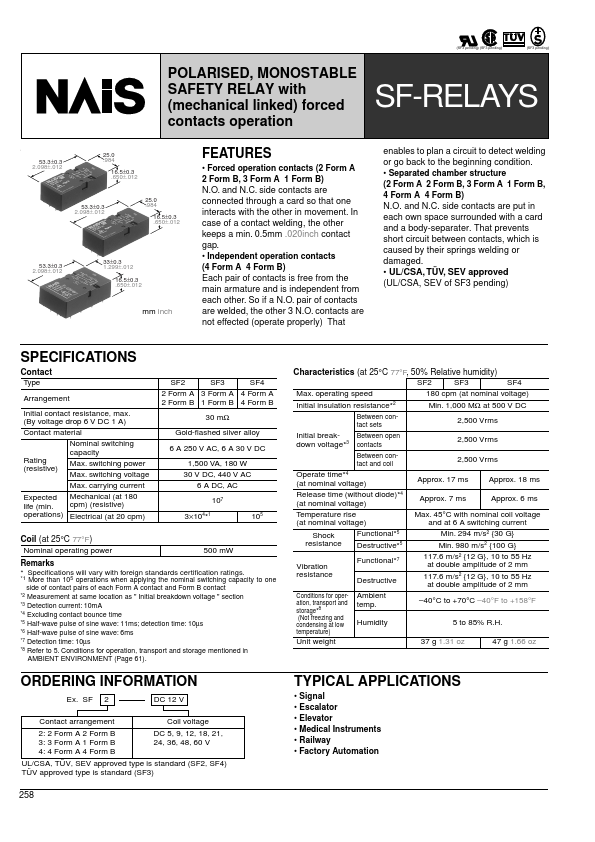

SF4-DC48V Description

Separated chamber structure (2 Form A 2 Form B, 3 Form A 1 Form B, 4 Form A 4 Form B) N.O. side contacts are put in each own space surrounded with a card and a body-separater. That prevents short circuit between contacts, which is caused by their springs welding or damaged.

SF4-DC48V Key Features

- Forced operation contacts (2 Form A 2 Form B, 3 Form A 1 Form B) N.O. and N.C. side contacts are connected through a car

- Independent operation contacts (4 Form A 4 Form B) Each pair of contacts is free from the main armature and is independe

- Specifications will vary with foreign standards certification ratings

.gif)