DCMZxxxxxx197 Overview

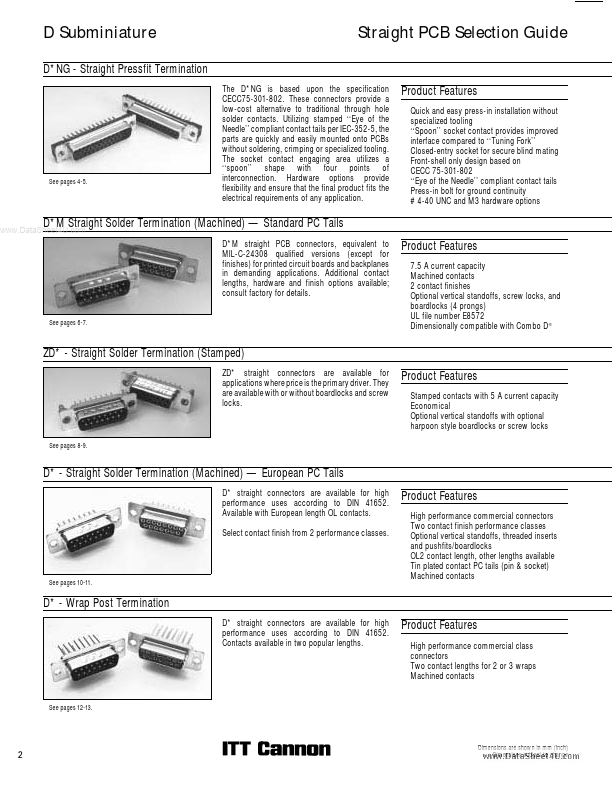

D Subminiature D NG - Straight Pressfit Termination Straight PCB Selection Guide See pages 4-5. The D NG is based upon the specification CECC75-301-802. These connectors provide a low-cost alternative to traditional through hole solder contacts.

DCMZxxxxxx197 Key Features

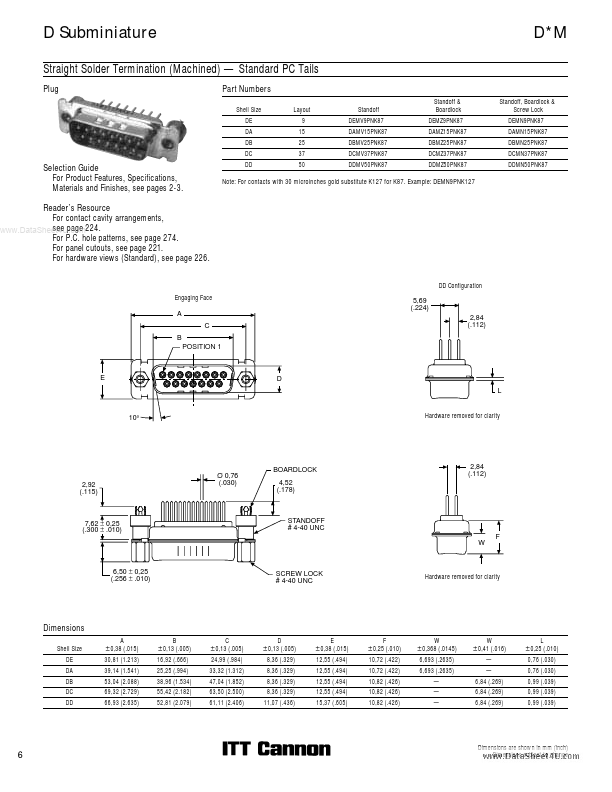

- Standard PC Tails