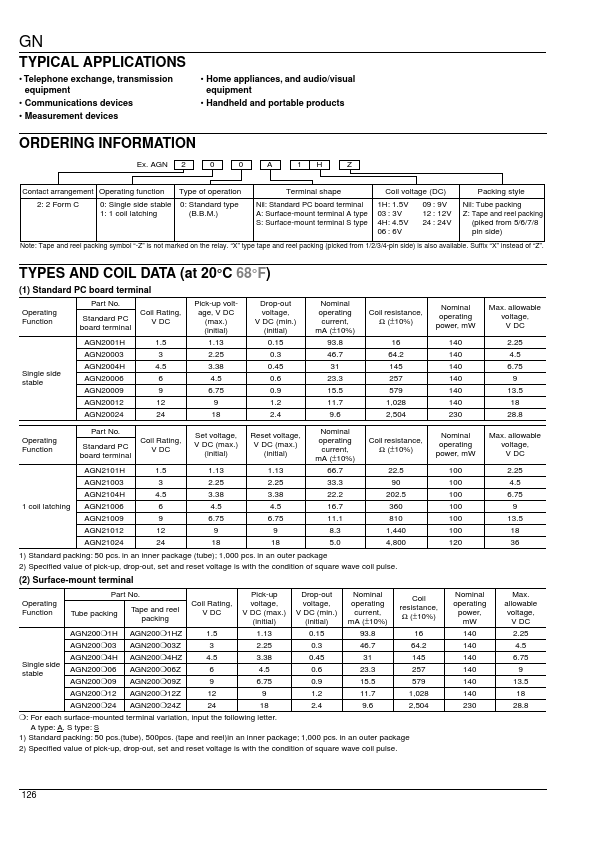

AGN20012 Description

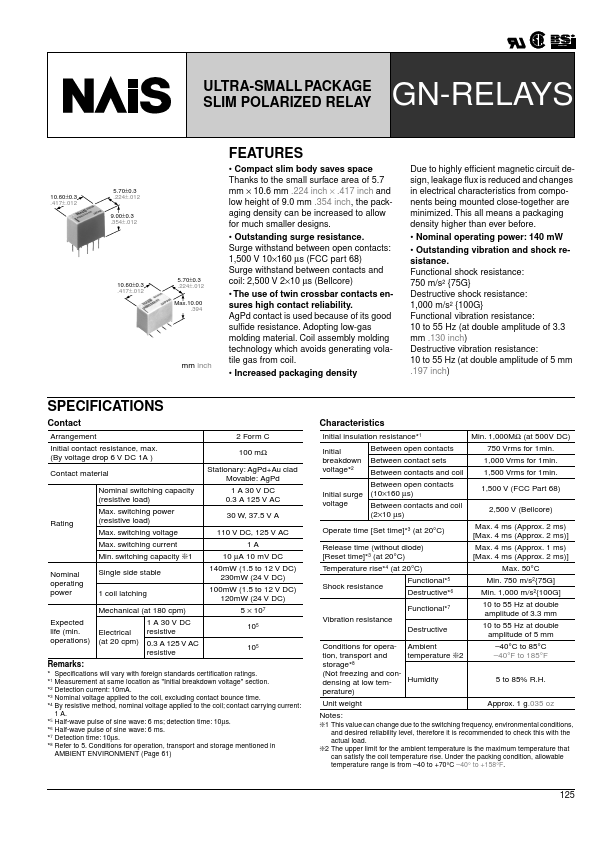

GNTESTING ULTRA-SMALL PACKAGE GN-RELAYSSLIM POLARIZED RELAY 10.60±0.3 .417±.012 5.70±0.3 .224±.012 9.00±0.3 .354±.012 10.60±0.3 .417±.012 5.70±0.3 .224±.012 Max.10.00 .394 mm.

AGN20012 Key Features

- pact slim body saves space Thanks to the small surface area of 5.7 mm × 10.6 mm .224 inch × .417 inch and low height of

- The use of twin crossbar contacts ensures high contact reliability. AgPd contact is used because of its good sulfide resi

- Increased packaging density

- Nominal operating power: 140 mW

- Specifications will vary with foreign standards certification ratings. -1 Measurement at same location as "Initial breakdo