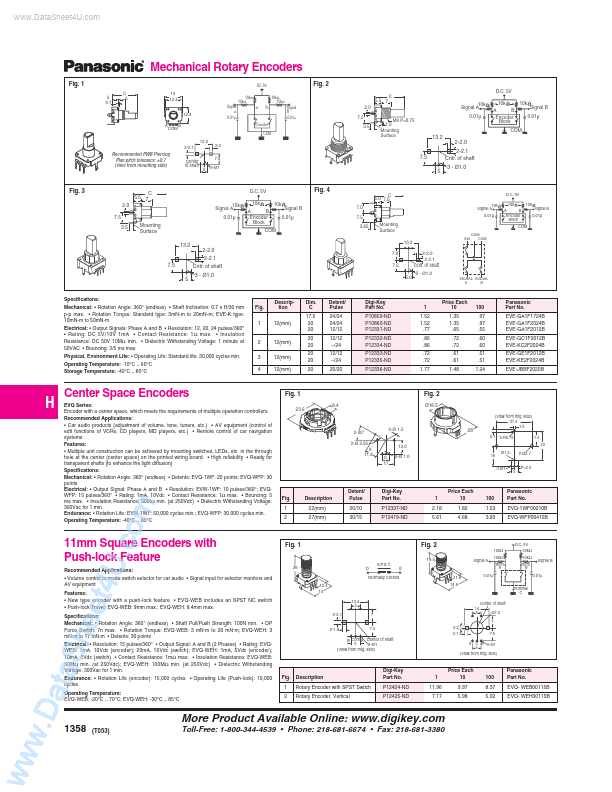

EVE-WEH00115B Description

Encoder with a center space, which meets the requirements of multiple operation controllers. Car audio products (adjustment of volume, tone, tuners, etc.) AV equipment (control of edit functions of VCRs, CD players, MD players, etc.) Remote control of car navigation systems.

EVE-WEH00115B Key Features

- Multiple unit construction can be achieved by mounting switches, LEDs, etc. in the through hole at the center (center sp

- High reliability

- Ready for transparent shafts (to enhance the light diffusion) Specifications: Mechanical

- Rotation Angle: 360° (endless)

- Detents: EVQ-1WF: 20 points; EVQ-WFP: 30 points Electrical

- Output Signal: Phase A and B

- Resolution: EVW-1WF: 10 pulses/360°; EVQWFP: 15 pulses/360°

- Rating: 1mA, 10Vdc

- Contact Resistance: 1Ω max

- Bouncing: 5 ms max