MA8100-M Overview

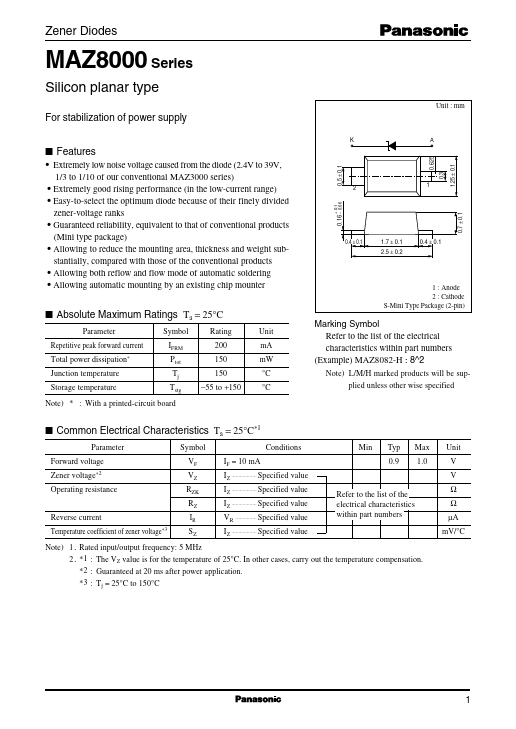

Zener Diodes MAZ8000 Series Silicon planar type Unit : mm For stabilization of power supply K A 0.625.

MA8100-M Key Features

- Extremely low noise voltage caused from the diode (2.4V to 39V, 1/3 to 1/10 of our conventional MAZ3000 series)

- Extremely good rising performance (in the low-current range)

- Easy-to-select the optimum diode because of their finely divided zener-voltage ranks

- Guaranteed reliability, equivalent to that of conventional products (Mini type package)

- Allowing to reduce the mounting area, thickness and weight substantially, pared with those of the conventional products

- Allowing both reflow and flow mode of automatic soldering

- Allowing automatic mounting by an existing chip mounter