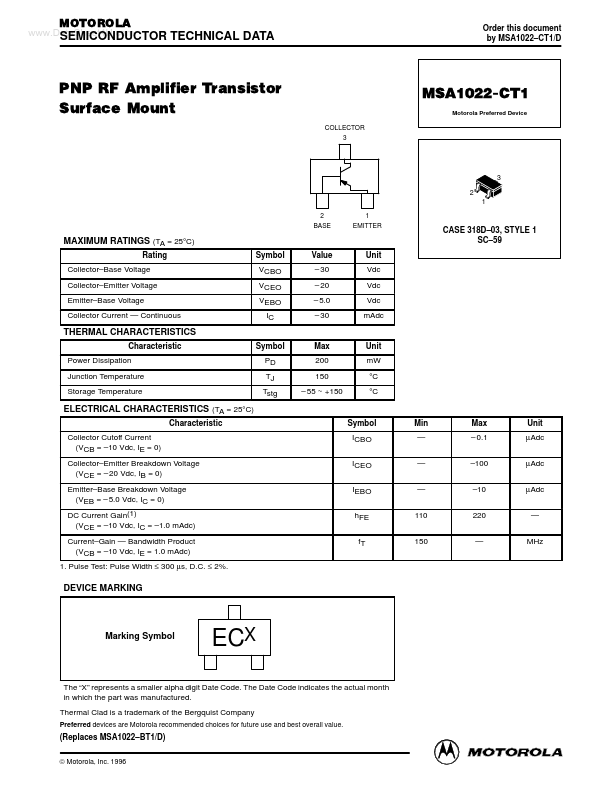

MSA1022-CT1 Description

Pulse Width ≤ 300 µs, D.C. Symbol ICBO ICEO IEBO hFE fT Min 110 150 Max 0.1 100 10 220 Unit µAdc µAdc µAdc MHz DEVICE MARKING Marking Symbol ECX The “X” represents a smaller alpha digit Date Code. The Date Code indicates the actual month in which the part was manufactured.